Glass etching

When casting glass I usually need to sandblast the glass after cold working in order to get a smooth and consistent texture across the piece. I usually use a 150grit medium at 35 psi or so.

Sandblasting will make everything really even and nice, but results in a very whitish, extremely scattery surface that lets little light shine through. The reason is that sandblasting essentially knocks tiny chunks out of the surface of the glass (every time a sand particle collides with the glass) and results in a surface that has lots of sharp edges, each refracting and scattering light. Any liquid or moisture on the surface will smooth the surface and make it more transluscent and thus oils from hands etc show up in really ugly ways.

To get a more consistently transluscent surface and no more finger prints you have two options to smooth the microscopic sharp edges. Either cover the glass in a varnish, like Liquid Luster. I don’t like this option because it just seems wrong to cover the glass in plastic. It also feels weird to touch and doesn’t look quite as nice. The other option is to lightly etch the glass - effectively rounding out the sharp edges, chemically. The disadvantage of this option is that it involves some quite dangerous chemicals. Silicates (SiO4) do not dissolve in much, but they are attached by hydroflouric acid and related compounds. HF is incredibly toxic and dangerous stuff - pretty much not feasible outside of a lab or an industrial setting.

Somewhat more managable but still very dangerous is Ammonium Biflouride. His Glassworks sells a product called Varietch which consists of ~50% Ammoniumbiflouride and ~50% sucrose (C12H22O11), sold as a powder. The sucrose is inert here and acts presumably as filler and also a hygroscopic, keeping the power wet-ish (you don’t want to inhale Ammoniumflouride powder). Or perhaps they add it to increase the viscosity of the solution ? I’m not sure. Either way you dissolve it in water and it etches glass very nicely at slightly reduced risk (You still need to use thick rubber gloves, a respirator and eye protection etc. Flouride poisoning is extremely dangerous).

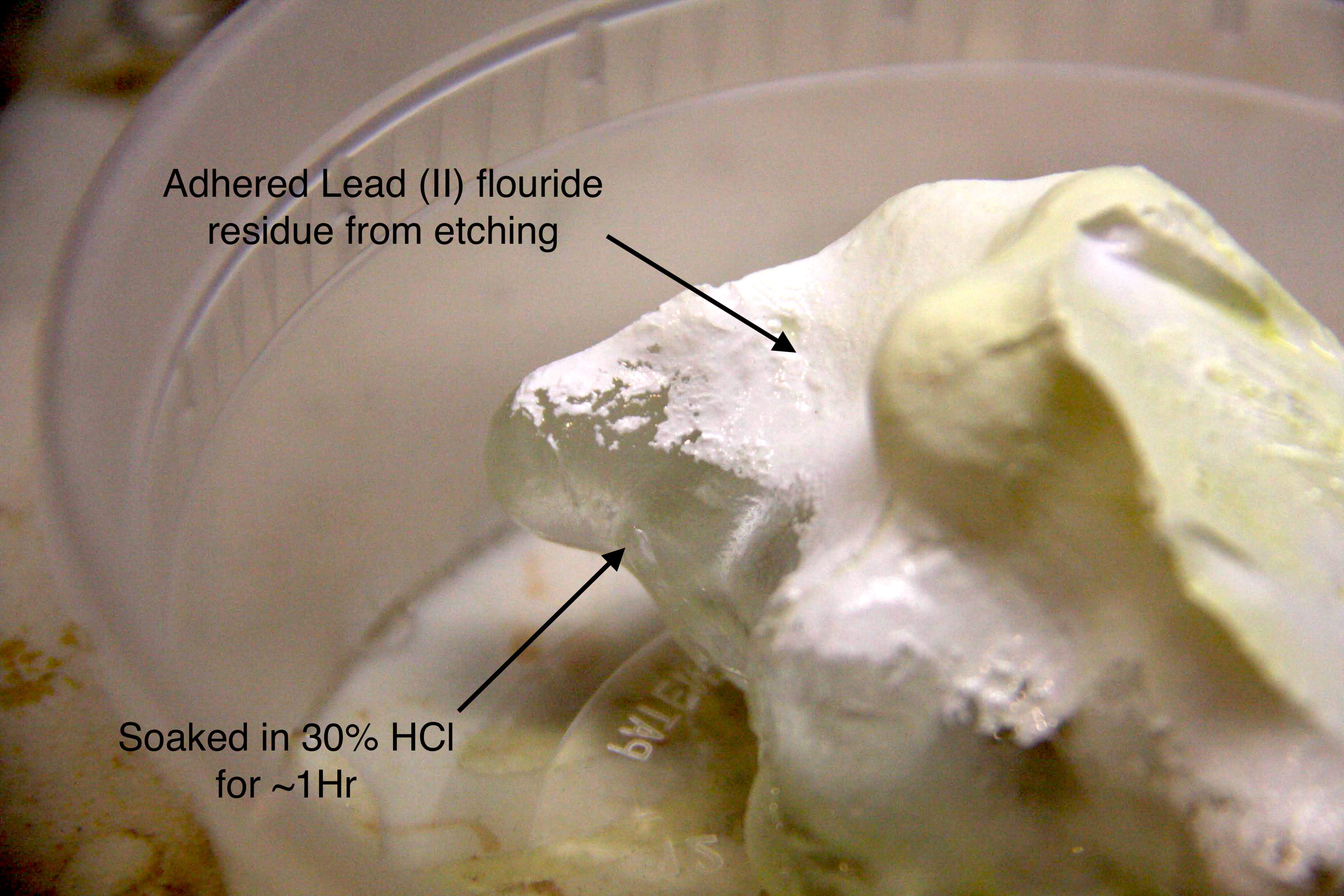

One problem I’ve encountered is with lead glass (crystal). Lead glass is beautiful and easier to cast (it less viscous at a given temperature). However when etching lead glass with ammonium biflouride the surface gets covered in a thick white substance which is insoluble and hard to scrub off. For years I’d just use muscle grease and scrub it off, or sometimes a pressure washer. I noticed that Soda glass does not form this residue. Recently I thought about what this stuff must be and came up with a better (albeit also hazardous) solution. Lead glass is a mixture of SiO4, PbO and K2O. Reacting with NH4HF2, these yield SiF4, PbF2 and KF. Now, the first and last are water soluble, but PbF2 is in fact a white, water-insoluble solid and thus most likely the white residue I find when etching my lead glass.

After some research I found that lead flouride (PbF2) is soluble in nitric and in hydrochloric acid. So I did two experiments to check my suspicion. First i etched a piece of lead glass and a piece of soda-lime glass. As expected, only the lead lead glass developed the residue. Second I got some muriatic (hydrochloric) acid from the hardware store (used to etch concrete). This is ~32% HCl. I soaked the residue covered piece of leadcrystal for ~ 1 hr and to my delight the residue was completely dissoved.

Obviously using concentrated hydrochloric acid is dangerous and needs to be done with great care and with good ventilation and safety equipment (Rubber gloves, Eye protection, Face shield, rubber apron). Note that all that is already necessary when dealing with the Varietch Ammoniumbiflouride, so it doesnt make the overall process much worse.

See also This paper

More notes:

32% HCl, dissolves within 1 hr 10% HCl, did not dissolve in 12 hrs.